REOMETRO D-MDR 3000

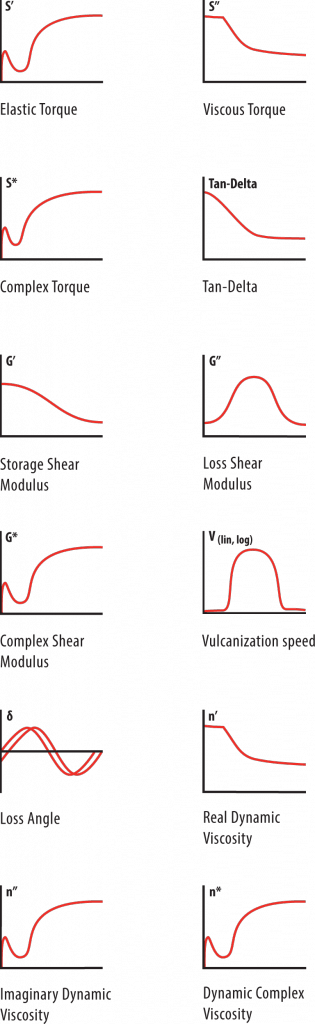

The D-MDR 3000 is designed for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data gives exact information about advanced material properties, processability, cure characteristics, cure speed, behavior of the compound at the after-cure and final compound dynamic mechanical properties, with an unlimited amount of testing steps and subroutines.

The D-MDR 3000 is the universal dynamic Moving Die Rheometer, providing the highest testing flexibility for static as well as dynamic testing applications for all kinds of rubber, rubber-like, curing or crosslinking materials. This includes, of course, all kinds of rubber materials filled with carbon black, silica or any other type of organic or inorganic filler, as well as TPE, TPV, LSR, and Composite Materials such as Prepregs, Polyolefins, Glues, Gelatine, …

InstrumentFor specific testing requirements MonTech offers a variety of instrument options to customize a testing solution exactly for your specific requirements: – Forced air and low-temperature cooling systems

Automation optionsAll MonTech Moving Die Rheometers as well as Rubber Process Analyzers can be easily automated, allowing customers to increase productivity and release operators for other important tasks.

Instrument options Instrument control panel with 5“ touchscreen display and printer; Torque transducer for low-viscosity torque range; Normal force / Pressure measurement; Cavity pressure control system; High speed data acquisition; Low-temperature cooling system MCool 10 / MCool -40; Autoloader 5 or 10 sample linear; Autoloader with 24, 48 or 100 sample tray or tray changers; R-VS 3000 constant volume sample cutter

|

CALCULATED RESULTS |