MDR 3000 Basic

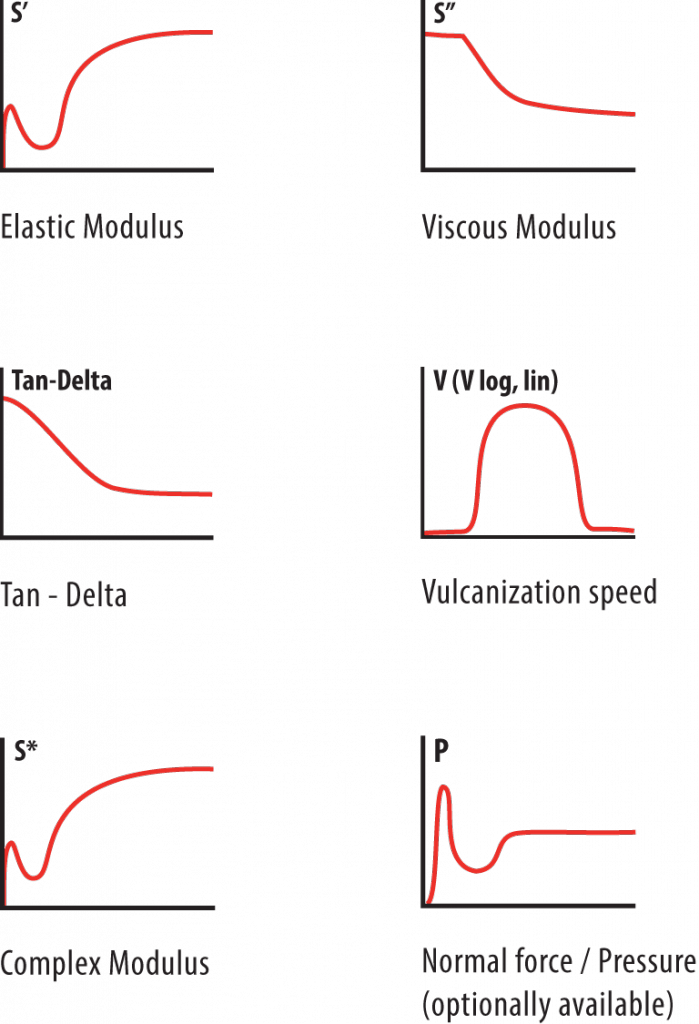

The MDR 3000 Basic is the easiest to operate and most cost-effective way to determine viscoelastic properties of polymers and rubber compounds before, during and after cure. The acquired data gives exact information about processability, cure characteristics, cure speed and the behavior of the compound after-cure, as well as optional pressure measurement for sponge rubber compounds.

The MDR 3000 Basic comes as a complete and ready-to-test set consisting of the Rheometer itself, an external Personal Computer with the latest Windows Operating System, TFT screen, keyboard and mouse, as well as a printer.

Instrument optionsFor specific testing requirements MonTech offers a variety of instrument options to customize a testing solution exactly for your specific requirements: – Forced air and low-temperature cooling systems

|

CALCULATED RESULTS |